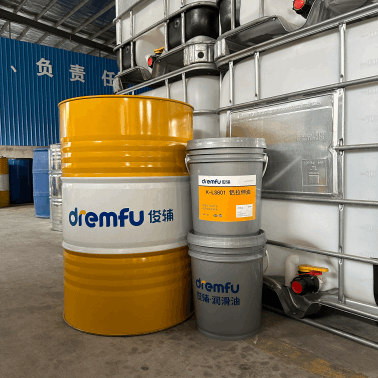

【Copper Stretching Oil–High-Performance Lubricant for Copper Drawing&Forming】

Our Copper Stretching Oil is specially formulated for high-speed,heavy-duty copper drawing and stretching applications.Designed for excellent lubrication,cooling,and oxidation stability,this advanced copper processing lubricant helps manufacturers achieve smoother surface finishes,higher production efficiency,and longer die life.

Whether you're producing copper wires,tubes,plates,or components for electrical,automotive,or communication industries,our Copper Stretching Oil ensures stable performance under continuous high loads and temperatures.

【Product Parameters】

Project | Typical Data |

kinematic viscosity at 40°C (mm²/s) | 30~35 |

flash point (°C) | >180 |

pour point (°C) | -10 |

Corrosion (100°C, 3H) steel, copper | qualified |

mechanical impurities | qualified |

moisture | / |

appearance | yellow transparent |

* The above parameters are for reference only. Please adjust them according to the actual processing conditions of your company as needed."

【Product Overview】

This premium Copper Stretching Oil provides superior film strength and extreme-pressure protection during copper drawing operations.The oil forms a consistent lubricating layer on the metal surface,reducing friction and preventing scratches,burns,and material breakage.Its fast cooling capability keeps the workpiece and dies at optimal operating temperatures,enabling long-term stable production.

Formulated with high-purity base oils and advanced additives,this metal forming lubricant delivers outstanding oxidation resistance and cleanliness,ensuring minimal residue and easy post-cleaning.

【Application Range 】

Medium-load stretching, stamping, and cutting of metals such as iron, carbon steel, copper, and aluminum.

![]() Copper Stretching Oil K-LS801.pdf

Copper Stretching Oil K-LS801.pdf

【FAQ】

1.What is Copper Stretching Oil used for?

Copper Stretching Oil is specifically designed for copper wire drawing,tube stretching,bar forming,and other cold working processes.It reduces friction,improves surface finish,and extends die life during copper forming operations.

2.Is this oil suitable for high-speed copper drawing?

Yes.The formula provides excellent film strength and cooling performance,making it ideal for high-speed and multi-pass copper wire drawing production lines.

3.Will it damage or corrode copper materials?

No.Our Copper Stretching Oil is non-corrosive and formulated to prevent oxidation,discoloration,or staining on copper and copper alloy surfaces.

4.Can this oil help improve the finish of drawn copper?

Absolutely.It significantly reduces scratches,surface defects,and burn marks,ensuring smoother and brighter copper surfaces after drawing.

5.How often should the Copper Stretching Oil be replaced?

Replacement intervals depend on production conditions,contamination levels,and drawing speed.We recommend regular filtration and monitoring to maintain stable performance and extend oil life.