【Product Performance】

Magnesium Alloy Cutting Fluid is a specialized coolant and lubricant designed for machining magnesium alloys, which are lightweight yet challenging to process due to their high reactivity and flammability. This fluid minimizes heat generation, prevents chip adhesion, and reduces tool wear while ensuring safety by suppressing sparks and hydrogen gas formation. Formulated with anti-corrosion additives and non-reactive base oils, it enhances surface finish and extends tool life. Its low-foam properties and excellent thermal stability make it ideal for high-speed operations like milling, turning, and drilling. Environmentally friendly variants are available to comply with industrial regulations.

【product parameters】

Testing Items | Parameters |

Appearance of the base oil |

Pale yellow, transparent |

Density | 1.06-1.09g·cm³(20°) |

Concentration | 35±1 |

PH value | 9±0.5 |

Appearance of the diluted solution | light cyan, semi-transparent |

【Usage method】

1. Before using this product, clean the machine, oil tank, or oil sump thoroughly. It is strictly prohibited to mix with other oils. Stir evenly before use.

2. Dilution ratio: Concentrate to water = 1:(1:20).

3. The concentration of the working fluid should not be lower than 5. Adjust the concentration of the working fluid appropriately according to different processing techniques, materials, and rust prevention requirements. For example: when processing stainless steel, the dilution ratio should be concentrate to water = 1:(1-10); when processing copper or aluminum alloys, the dilution ratio should be concentrate to water = 1:(1-20).

4. Note: For rust prevention, after 3 days, water can be added at a ratio of 10:1. After 7 days, water can be added at a ratio of 5 to 7 parts water to 1 part concentrate. After 10 to 15 days, water can be added at a ratio of 3 to 5 parts water to 1 part concentrate.

Our Full Synthetic Cutting Fluid is specially formulated for high-performance machining of magnesium alloys and other non-ferrous metals.Designed to provide superior lubrication and cooling,this synthetic grinding coolant significantly reduces tool wear and enhances surface finish.

Unlike traditional oils,our Full Synthetic Cutting Fluid offers excellent thermal stability,ensuring consistent performance under high-speed cutting conditions.Its low-foaming and non-corrosive formula protects both the machine and the workpiece,minimizing downtime and maintenance costs.

【Key Features:】

High Lubricity:Reduces friction and tool wear,extending tool life.

Excellent Cooling:Maintains optimal temperature during high-speed machining.

Non-Corrosive:Safe for magnesium alloys and precision equipment.

Eco-Friendly Formula:Biodegradable and compliant with industrial safety standards.

【Applications:】

Milling,drilling,and grinding of magnesium alloys.

Precision machining of aluminum,copper,and other non-ferrous metals.

Ideal for CNC machines,grinding centers,and high-speed machining operations.

Benefits of Using Full Synthetic Cutting Fluid:

Enhanced Surface Finish:Achieve smoother surfaces with reduced burrs.

Extended Tool Life:Lower friction reduces tool replacement frequency.

Reduced Machine Downtime:Prevents overheating and corrosion.

Cost-Effective Production:Improves machining efficiency while reducing waste.

To get the most out of your machining process,pair our Full Synthetic Cutting Fluid with proper maintenance and monitoring.This ensures consistent performance,longer tool life,and improved product quality.

【F&Q】

Q1:What is Full Synthetic Cutting Fluid used for?

A:Our Full Synthetic Cutting Fluid is designed for high-performance machining of magnesium alloys,aluminum,copper,and other non-ferrous metals.It provides excellent lubrication and cooling,reducing tool wear and improving surface finish.

Q2:How does Full Synthetic Cutting Fluid improve machining performance?

A:By maintaining optimal temperature and reducing friction during cutting,Full Synthetic Cutting Fluid enhances tool life,prevents overheating,and ensures smoother surfaces,especially in precision CNC machining.

Q3:Can Full Synthetic Cutting Fluid be used on all types of metals?

A:While it is ideal for magnesium alloys,aluminum,and copper,it can also be used on other non-ferrous metals.Avoid using it on ferrous metals without testing,as its formulation is optimized for non-ferrous applications.

Q4:Is Full Synthetic Cutting Fluid safe for machines and operators?

A:Yes.Our cutting fluid is non-corrosive,low-foaming,and biodegradable,ensuring both machine protection and operator safety.It meets industrial safety standards.

Q5:How should I apply Full Synthetic Cutting Fluid for best results?

A:Apply it according to the recommended flow rate for your machine and machining process.Ensure proper maintenance of the fluid and regularly check for contamination to maximize efficiency and prolong tool life.

Q6:What are the benefits of using Full Synthetic Cutting Fluid compared to conventional oils?

A:It offers superior cooling,reduces tool wear,improves surface finish,minimizes downtime,and is environmentally friendly,making it more cost-effective in high-speed machining operations.

Q7:Where can I buy Full Synthetic Cutting Fluid?

A:You can find our full range of synthetic grinding coolants,including the Full Synthetic Cutting Fluid,directly on our product page

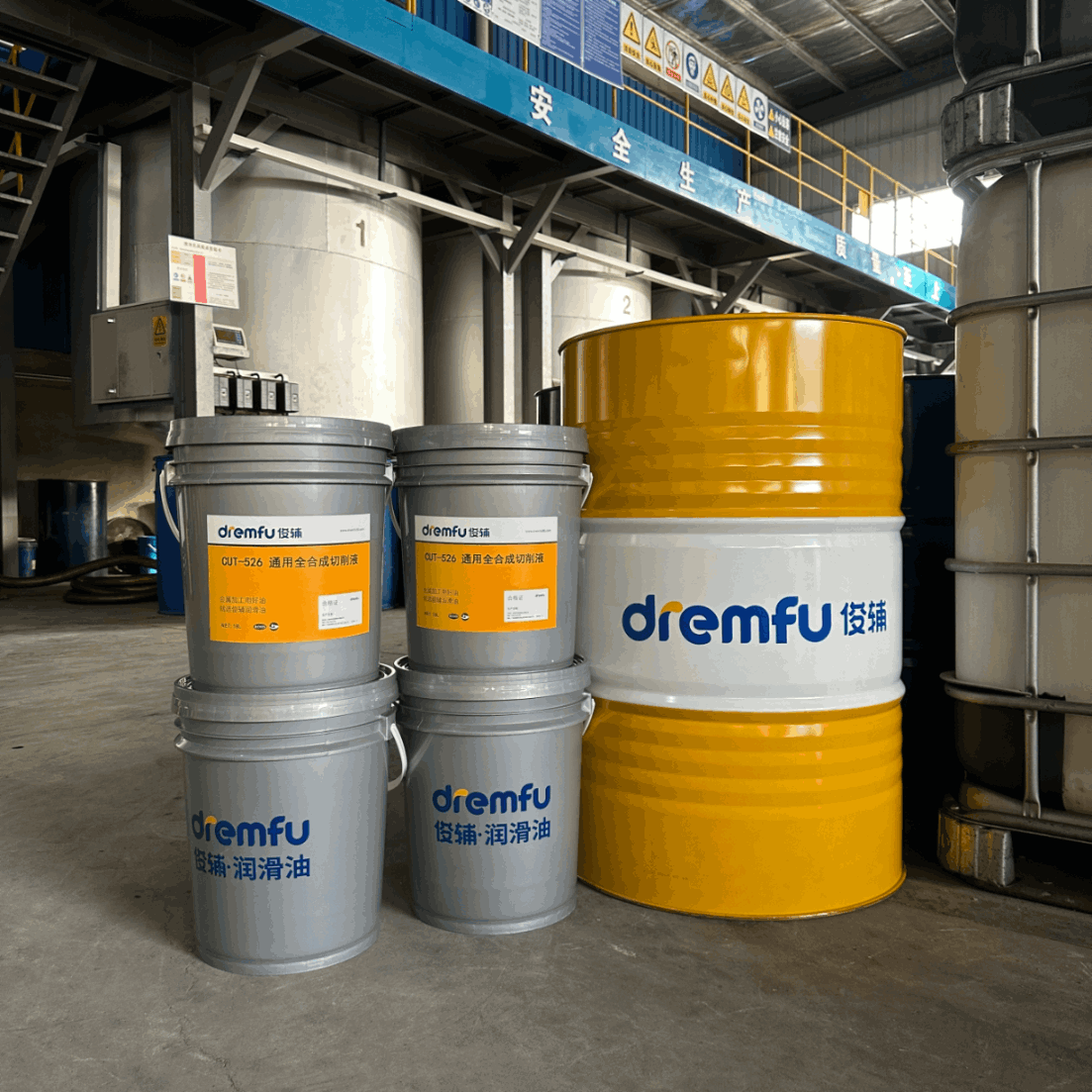

【Packaging specifications】

18L per plastic drum, 200L per large iron drum

【Precautions】

1. Due to different production batches, there may be variations in the color of the cutting fluid, which does not affect normal use.

2. This product should be stored in a dry, cool, and well-ventilated warehouse. During storage and transportation, exposure to sunlight and rain should be avoided.

Looking for a reliable Magnesium Alloy Cutting Fluid to improve both safety and efficiency in your machining process? Contact us today to request a technical data sheet or free sample. Our team will provide tailored recommendations to match your specific production needs.