Our products are utilized across a range of industries

Providing effective lubrication solutions, expert technical support, and personalized one-on-one service to our customers

Dremfu Lubricants has over 20 years of industry experience in processing liquids for hard and brittle materials such as glass and quartz. We primarily handle the following products: glass Cutting Fluid, glass edge grinding oil, glass Cutting Oil, internal circular cutting fluid, sapphire cutting fluid, sapphire wire cutting fluid, sapphire ceramic rod fluid, sapphire polishing fluid, quartz Glass Cutting Fluid, Ceramic Cutting Fluid, silicon wafer cutting fluid, semiconductor cutting fluid, glass cleaning agents, glass wax remover, glass adhesive remover, and glass film remover. We offer a one-stop service for cutting, grinding, drilling, and cleaning.

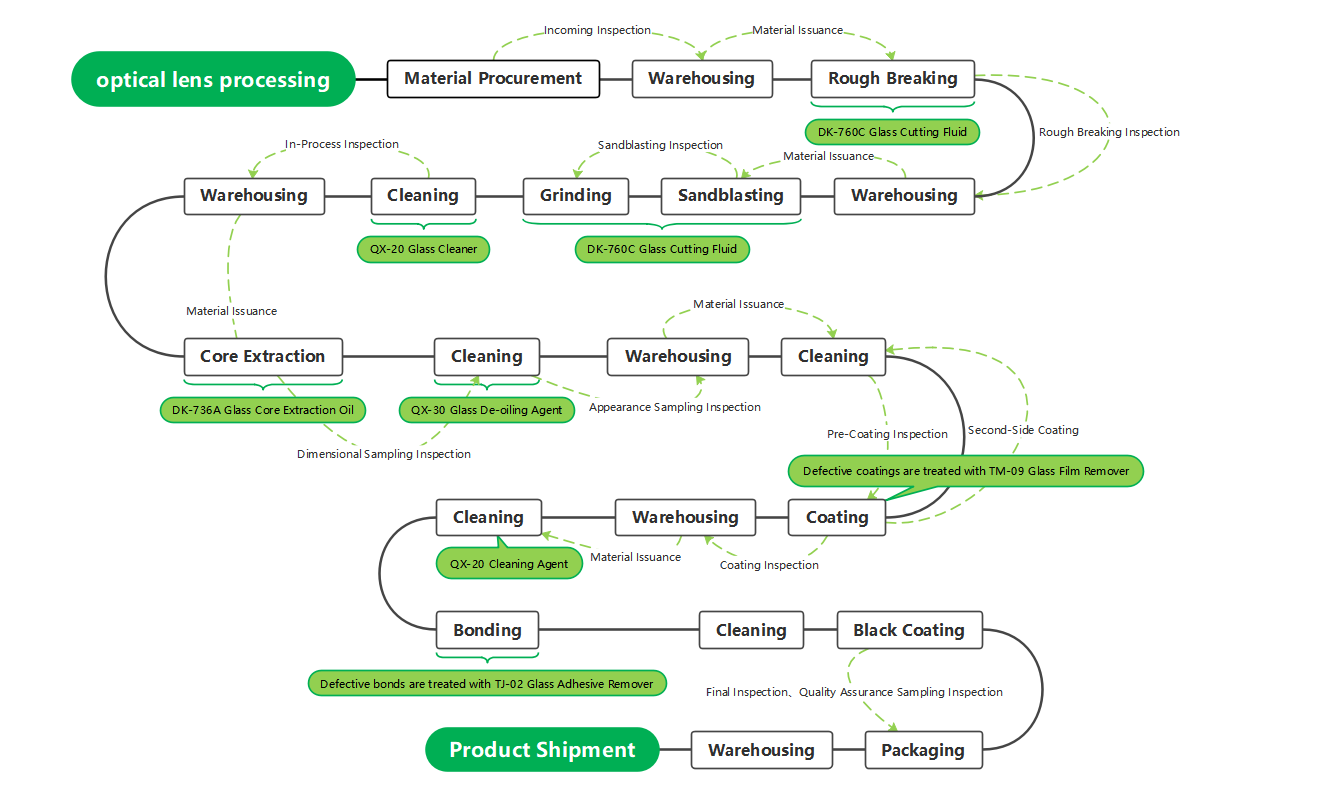

In the optical lens processing, our products used include DK-760C Glass Cutting Fluid, QX-20 Glass Cleaner, DK-736A Glass Core Extraction Oil, QX-30 Glass De-oiling Agent, TM-09 Glass Film Remover, and TJ-02 Glass Adhesive Remover. (As shown in the image below)

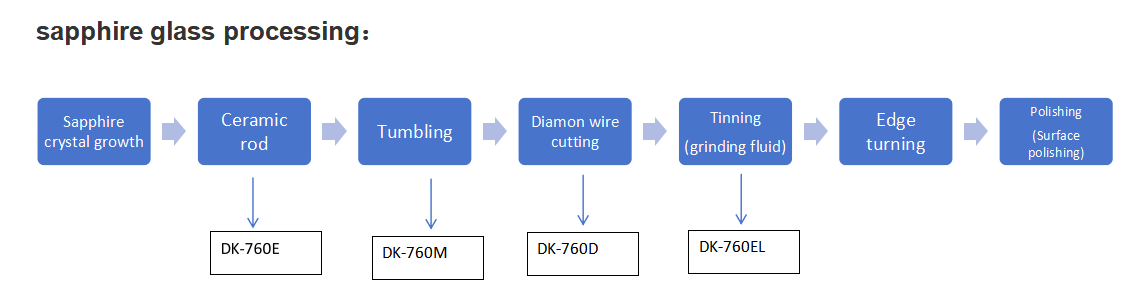

In the sapphire glass processing, our products used include DK-760E Sapphire Ceramic Rod Fluid, DK-760M Sapphire Cutting Fluid, DK-760D Sapphire Wire Cutting Fluid, and DK-760EL Sapphire Polishing Fluid (also known as Suspension Fluid or Dispersant). (As shown in the image below)

Dremfu lubricants offer tailored recommendations for processing hard and brittle materials, depending on the process, material, and equipment. For example, for cutting glass used in doors, windows, or curtain walls, we recommend our "Water-Washable Glass Cutting Oil DK-605." For CNC processing of zirconia ceramics, we suggest our "Ceramic Cutting Fluid DK-760C5." For cutting microcrystalline glass with diamond wire, we recommend our "Microcrystalline Glass Cutting Fluid DK-760C6." For more recommendations, follow Dremfu Lubricants for personalized one-on-one service.

Dremfu lubricants for processing hard and brittle materials such as glass, quartz, ceramics, silicon wafers, and sapphire are commonly used in various industries, including the mobile phone industry, medical industry, telecommunications industry, military industry, home appliance industry, home decoration industry, electronics industry, optoelectronics industry, photovoltaic industry, construction industry, medical devices, aerospace industry, and chemical industry, among others. Our products have a wide range of applications and currently cover over 50 industries.

Common Issues | Common Reasons | Solutions |

Strong and Pungent Odor | Contamination or Naturally Strong Odor of the Processing Fluid | Check for oil leaks or use cutting fluids with lower odor |

Skin Allergies or Hand Injuries | High Concentration/PH Value of Working Fluid or Presence of Irritating Components | Adjust the concentration/PH value of the working fluid or switch to a different working fluid |

Slow Processing Efficiency | Poor Lubrication Leading to Weak Grinding Force | Switch to a processing fluid with stronger lubrication properties |

White, paste-like substance at the bottom of the machine tool | Lack of a settling agent in the glass grinding fluid, leading to significant accumulation of glass powder | Add a small amount of settling agent and regularly clean the machine tool. Install a filtration system to filter out settled particles. |

During the glass cutting process, glass powder mixes with the glass cutting fluid | Insufficient or missing settling agent | Add a settling agent to enable the glass powder to quickly settle in the liquid. |

| Product Chipping, Scratching, or Cracking | Damage Due to Poor Lubrication or Poor Settling of Powder | Switch to high-quality cutting fluid with better lubrication properties |

| The glass processing fluid has an unpleasant odor, negatively impacting the production environment | ①The grinding fluid contains a significant amount of bacteria. ②Improper maintenance, with grinding fluid not being replaced or cleaned in a timely manner. | Regularly clean the machine to prevent bacterial growth. |

| Rapid Tool Wear and High Production Costs | Inadequate Lubrication, Failing to Achieve Effective Production Lubrication | Switch to a processing fluid with stronger lubrication properties |

Select appropriate cutting oil types based on processing scenarios and requirements:

| Type | Applicable Scenarios | Core Advantages |

|---|---|---|

| Water-Soluble Cutting Oil | Special-shaped cutting (e.g., automotive glass), thick glass (12-25mm) cutting | - Strong lubricity, extending tool life by over 30% - Fully water-washable, reducing process costs - Reduces glass debris, improving cut quality |

| Volatile Cutting Oil | Flat glass (online/offline), coated glass (e.g., LOW-E glass), small-size offline cutting | - Complete evaporation without residue, avoiding coating damage - Supports variable evaporation rates (fast/medium/slow models) - Low odor, safe operation |

| Fully Synthetic Cutting Oil | Manual cutting, laminated glass, gemstones, ultra-thin glass (e.g., electronic optical glass) cutting | - Excellent lubrication and cooling performance - Low viscosity for precision machining - Compatible with multiple materials (silicon, germanium, ceramics) |

| Specialized Models | Foam glass insulation boards (MB105), ceramic-printed glass (active additive formula) | - Optimized performance for special materials - Enhances processing stability and yield |

2. Key points of performance optimization

Lubrication and cooling:

Add oil-based and anti-wear agents to reduce tool wear (extend tool wheel life by more than 30%).

Quickly remove cutting heat (reduce temperature by more than 30%) to avoid glass cracking due to thermal stress.

Settlement and cleaning:

Powder settling agent quickly removes cutting debris and keeps the processing environment clean.

After processing, the workpiece can be directly washed with water to improve the quality of subsequent processes such as coating and bonding.

Permeability:

Volatile glass cutting oil (such as DR-206) enhances the wettability with the glass surface to prevent "edge explosion" and ensure a smooth cut.

2、 Environmental Protection Solutions

1. Replace traditional mineral oil

Synthetic ester/water-based environmentally friendly oil:

Biodegradable, reducing the cost of waste liquid treatment.

Compliant with the "Emission Standards for Air Pollutants in the Glass Industry" (such as the NOx limit of 300-350mg/m ³ in Hebei, Shandong and other places).

Low volatile formula:

Reduce VOCs emissions and avoid health risks for workers (such as respiratory and liver damage caused by kerosene).

2. Waste oil treatment measures

Recycling:

Extend the service life of oil products and reduce replacement frequency through a filtration system.

Professional recycling:

Collaborate with environmental protection agencies to regenerate or harmlessly dispose of waste oil, in compliance with the requirements of the Solid Waste Pollution Prevention and Control Law.

3、 Application scenarios and pain point solutions

1. Architectural glass processing

Pain points: Cutting large-sized glass is prone to edge breakage and high transportation losses.

Plan:

Use high viscosity fully synthetic oil (such as DK-605) in conjunction with an automatic cleaning system to ensure a smooth cutting surface.

Reduce transportation damage rate and improve product yield.

2. Automotive glass processing

Pain points: High precision is required for irregular cutting, and coated glass is prone to damage.

Plan:

Volatile cutting oil (such as DR-206), combined with slow evaporation characteristics, is suitable for high-temperature online cutting.

Avoid film residue and improve the processing quality of coated glass.

3. Electronic optical glass processing

Pain point: Ultra thin glass (such as 0.1mm) is prone to microcracks.

Plan:

Nano additives enhance lubricity, combined with low viscosity oils (such as Junfu lubricant DR-206).

Realize precise non-destructive cutting to meet high-precision requirements such as AR/VR and vehicle optics.

Dremfu processing fluids are formulated using high-quality base oils and various imported additives. This ensures stable performance during processing, with a mild and non-irritating formula that is gentle on the skin. Our fluids have excellent powder settling properties, do not stick to the machine, enhance processing efficiency, and ensure high product quality.

Dremfu lubricants use a targeted recommendation approach, with experienced sales personnel providing one-on-one service. We first understand your specific needs and then make tailored recommendations, deeply addressing your lubrication challenges.

With a strong R&D team of over 10 technical engineers, Dremfu boasts an independent laboratory and comprehensive testing equipment. We offer custom solutions based on samples or performance requirements and provide MSDS material safety data sheets and SGS third-party test reports.

With over 10,000 square meters of self-built facilities and a stock of more than 200 tons of raw materials, Dremfu operates an automatic oil blending production line with unlimited capacity. We offer same-day shipping for standard products upon order, and some products can be shipped within 3 days.

We have established strategic partnerships with international logistics companies such as Daliang Logistics, Datong Logistics, and Zhenhua Logistics. Additionally, Dremfu assigns dedicated personnel to oversee the entire process, ensuring timely delivery for every order.