【Product Performance】

CUT-813B Cutting Oil is specially designed for titanium alloy, carbide and a special cutting oil, with superior anti-sintering function and anti-friction characteristics, can greatly reduce tool wear, improve the surface quality of the workpiece, this oil is not suitable for copper processing.

【Product Parameters 】

Project | Typical Data | Test Method |

Appearance | Light yellow transparent | Visual inspection |

smell | Low odor | - |

density(20℃) | 0.82~0.87 | hydrometer |

Kinematic viscosity 40°C (mm²/s) | 21~23 | GB/T 265 |

Flash point (°C) | >165℃ | GB/T 267 |

Mechanical impurities | Up to standard | GB/T 511 |

【Performance Characteristics】

★ Lubricity: Possesses excellent extreme pressure and friction reduction properties, with superior anti-seizure function, effectively ensuring the surface brightness of the processed parts and extending tool life.

★ Excellent Cooling: Capable of removing the heat generated by intense friction during high-speed machining, reducing odor and component deformation to minimal levels.

★ Excellent Operability: Transparent in color, making it easy to observe the workpiece during machining. Low odor and low oil mist, making it easy for operators to adapt.

Titanium Alloy Cutting Oil: Key Characteristics and Performance Data

1. Exceptional Lubricity (Coefficient of Friction ≤0.08)

Specially formulated extreme pressure (EP) additives create a durable lubricating film, reducing tool-workpiece friction to ≤0.08 coefficient (ASTM D2714). This minimizes built-up edge formation while extending tool life by 300-400% compared to standard oils in continuous machining operations.

2. High-Temperature Stability (Flash Point ≥240°C)

With a flash point exceeding 240°C (ASTM D92), the oil maintains stable viscosity (ISO VG 68) even at cutting zones reaching 600-800°C. Thermal conductivity of 0.12 W/m·K ensures efficient heat dissipation from critical contact areas.

3. Advanced Anti-Welding Properties (Weld Load ≥3,500N)

Contains sulfur-phosphorus composite additives achieving 3,500N weld load protection (Four-Ball Test, ASTM D2596). This prevents material adhesion during high-speed operations (100-250 m/min cutting speeds) common in aerospace component manufacturing.

4. Corrosion Inhibition (98% Protection Rating)

Passes 500-hour salt spray tests (ASTM B117) with 98% protection efficiency. The amine-free formulation provides pH stability (8.5-9.2) while being compatible with titanium alloys (Grade 5 Ti-6Al-4V) and machine tool materials.

5. Chip Control Enhancement (30% Reduction in Chip Adhesion)

Proprietary polar additives lower surface tension to 28-32 dynes/cm, improving chip breakability by 30% and reducing swarf adhesion in deep-hole drilling (aspect ratios >10:1).

6. Environmental Compliance (Biodegradability >80%)

Formulated with >80% biodegradable base oils (OECD 301B) and zero chlorine content. Meets ISO 14000 standards with VOC emissions <50g/m³, suitable for enclosed CNC systems with mist filtration requirements.

【Scope of Application】

●Recommended for titanium alloy, carbide material, milling, drilling, tapping, punching machine, etc. This product is not suitable for copper processing.

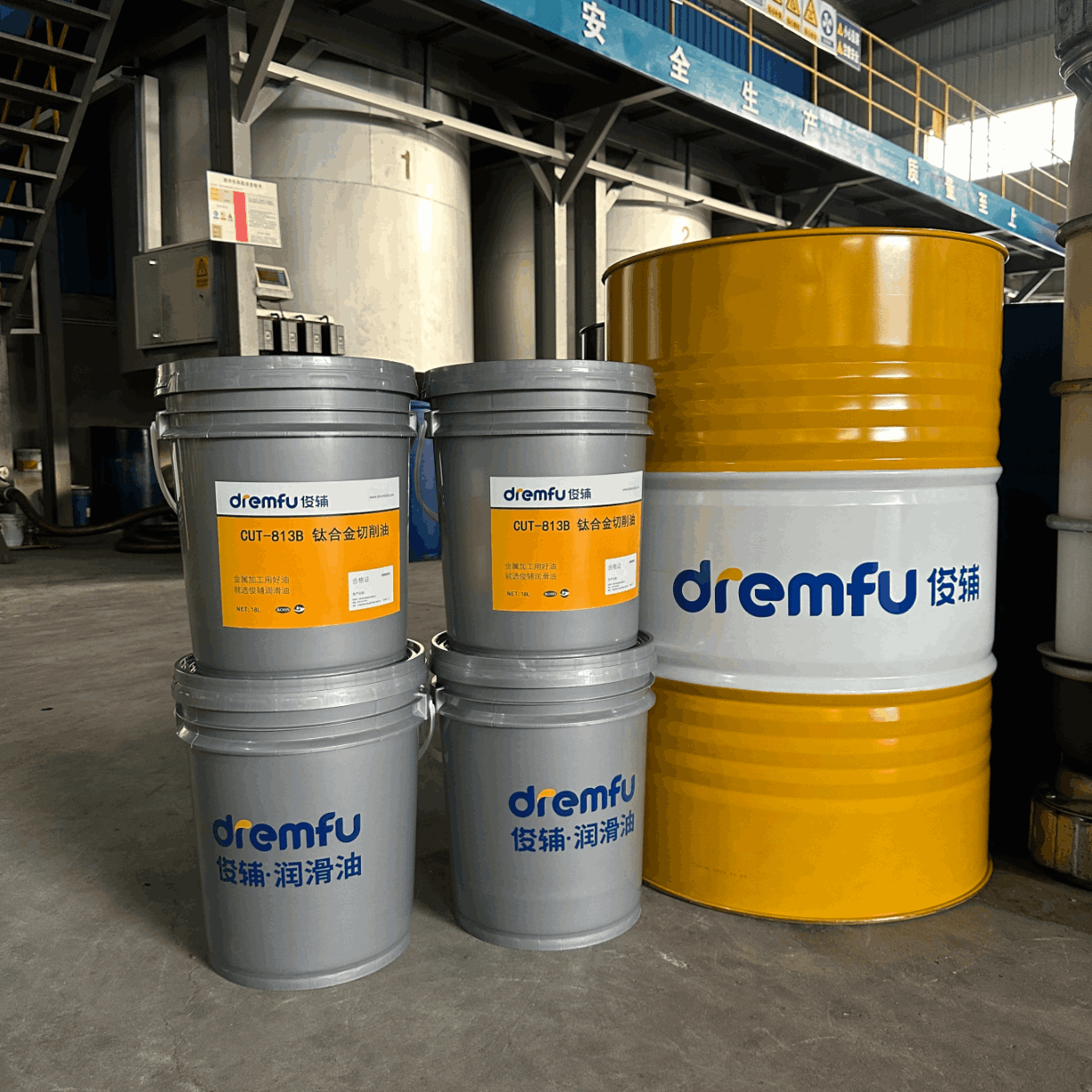

【Packaging Specifications 】

18L/ plastic bucket, 200L/ large iron bucket.