Our products are utilized across a range of industries

Providing effective lubrication solutions, expert technical support, and personalized one-on-one service to our customers

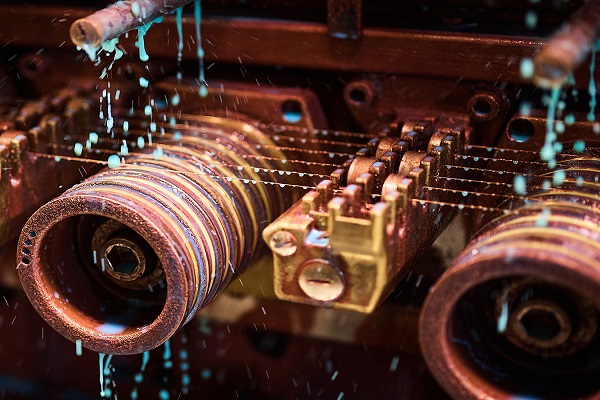

Dremfu wire drawing liquid is an indispensable industrial additive in the wire drawing production process. It can reduce the wear of metal wire and eye mold in the wire drawing process and obtain good cooling, cleaning and anti-oxidation effects. It is widely used in wire drawing of copper, aluminum, iron, stainless steel and other wires.

The selection of wire drawing liquid is related to factors such as equipment, process, material, etc. According to the material, it is divided into copper wire drawing liquid, aluminum wire drawing liquid, iron wire drawing liquid, stainless steel wire drawing liquid, etc. The process includes large drawing, medium drawing, small drawing and micro drawing. Different wire drawing degrees choose different wire drawing liquids. How to choose wire drawing liquid? Pay attention to Dremfu lubricating oil and recommend suitable wire drawing liquid for you.

Dremfu wire drawing liquid is often used in cable industry, machinery manufacturing industry, hardware processing industry, petrochemical industry, plastic industry, bamboo and wood products industry, construction industry, automobile industry, aviation industry, electronics industry and other industries

Common Issues | Common Reasons | Solutions |

Too much foam in the drawing liquid | 1. Too much surfactant dosage; 2. Improper operation; 3. Impure water quality. | 1. Reduce the amount of surfactant; 2. Improve the operation method; 3. Improve the water quality; 4. Add foam inhibitor; |

Wire breakage | Caused by insufficient lubricity. | Switch to drawing oil that is easy to clean. |

Drawing fluid stinks | Bacteria breed and corrode the emulsifier, causing the pH value to drop. | Use a bactericide or switch to a wire drawing liquid with better anti-corruption effect. |

Wire oxidation discoloration | The anti-oxidation effect of wire drawing liquid is poor. | Use a drawing fluid containing antioxidants. |

Select appropriate drawing oil types based on material, processing complexity, and requirements:

| Material/Process | Recommended Oil Type | Core Advantages |

| Stainless Steel Drawing | S890 (Sulfurized Lard Oil Base) | - Excellent extreme pressure (EP) and anti-wear properties, preventing cracks and scratches - Extends mold life by over 30% |

| Aluminum Drawing | S895 (Low-Viscosity Oil/Water-Based) | - Low viscosity for easy cleaning, avoids sticking and scratches - Compatible with aqueous cleaning processes |

| High-Strength Steel/Complex Shapes | Chlorinated Paraffin T301/Sulfurized Fatty Acid Ester Additives | - Reinforces oil film strength, reduces mold wear by 20% - Controls heat buildup (temperature reduction of 20-30%) |

| Copper/Titanium Alloy | DeoAdd 1411 (Non-Active Sulfur Additive) | - Prevents material reaction, ensures surface smoothness - Low odor, non-corrosive |

1.Key points of performance optimization

Lubrication and extreme pressure performance:

Sulfurization additives (such as sulfurized lard) reduce the friction coefficient by more than 30%, reducing the risk of scratches and cracking.

Extreme pressure agents (such as chlorinated paraffin) form a tough boundary film that is suitable for high load processing.

Cooling efficiency:

Water based oil quickly absorbs heat, controls temperature rise (20-30% cooling), and prevents thermal deformation of the workpiece.

Rust prevention and cleaning:

Triethanolamine rust inhibitors provide short-term anti-corrosion protection.

Dilute with water-soluble oil (such as 1:10) to reduce cleaning time by 50% (applicable to aluminum materials).

2、 Environmental Protection Solutions

1. Traditional oil substitution solutions

Water based stretching oil:

Plant ester formulas (such as synthetic esters) have a biodegradation rate of over 90% and reduce VOC emissions by 80%.

Compliant with ISO 14001 standard (VOC ≤ 50g/L), free of heavy metals, chlorine, and nitrite.

Synthetic ester oil:

Low volatility, non-toxic and odorless, suitable for closed-loop circulation systems.

2. Waste oil treatment measures

Recycling:

The filtration system removes metal debris, extending the lifespan of the oil by 2-3 cycles.

Professional recycling:

Cooperate with certification agencies to regenerate or incinerate electricity, in compliance with the Solid Waste Pollution Prevention and Control Law.

3、 Application scenarios and pain point solutions

1. Automotive parts processing

Pain points: Scratches caused by stamping of high-strength steel; Residual galvanized sheet affects electrophoresis.

Plan:

Low residual high extreme pressure water-based oil (such as SR-7014 composite agent)+automatic cleaning to ensure surface cleanliness (residual<0.1%).<>

2. Stretching of household appliance shells

Pain point: Thin plate stretching deformation; The smell of oil is pungent.

Plan:

Volatile stretching oil (such as volatile stamping oil) does not require post cleaning and has ROHS certification for low odor.

3. Processing of electronic device casings

Pain points: Stretching cracking of ultra-thin aluminum materials; Oil residue hinders assembly.

Plan:

Ultra low viscosity water-based oil (diluted 1:10)+extreme pressure lubrication, with cleaning residue<0.1%.<>

Dremfu wire drawing liquid is developed with semi-synthetic technology and imported additives. It is suitable for use in various wire high-speed wire drawing machines. It has stable performance and excellent performance in different use environments. At the same time, it is used with equipment from famous wire drawing machine manufacturers such as Nihoff, Samp, Hongtai and Yongxiong.

Dremfu lubricating oil adopts a targeted recommendation method, and senior business personnel provide one-to-one service, first understand and then recommend, and deeply solve the oil problem for customers.

Independent laboratory and complete testing equipment, free sample testing and customization, and can provide SGS, MSDS, ROHS and other test reports.

It has a self-built factory building of more than 10,000 square meters and an automated oil blending production line. The annual output can reach 300,000 tons, and conventional products are shipped within 3 days.

It has reached strategic cooperation with many international logistics companies such as Ocean Logistics, Datong Logistics, Zhenhua Logistics, etc. At the same time, Junfu Company has sent a dedicated person to follow up throughout the process to ensure that each order is delivered on time.